Summit truck bodies are engineered for strength and durability, built with premium materials and quality manufacturing.

20 Series

Although we have never built two the same, we will fully equip your truck as needed to face your biggest jobs. Many of these truck bodies are designed for versatility, so mechanics can get any job done in the most remote work site.

You will have the payload capacity and storage space to carry all the tools and equipment to the most remote job sites to finish any job safely in arduous conditions. For example, the 20 Series truck body can carry tools for complete repair work and lube equipment to perform preventative maintenance.

Highlights

20 Series

Common Applications

This 20 Series can be the ultimate workshop custom-designed for any industry application. We have equipped this body for forestry, mining, and heavy construction applications. Tailor the custom heavy duty truck body as a lube-service combo or for specialized work, such as line-boring.

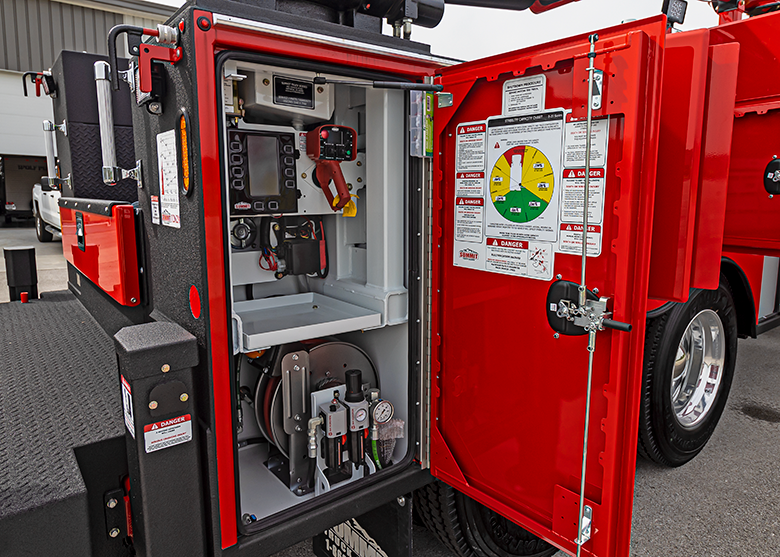

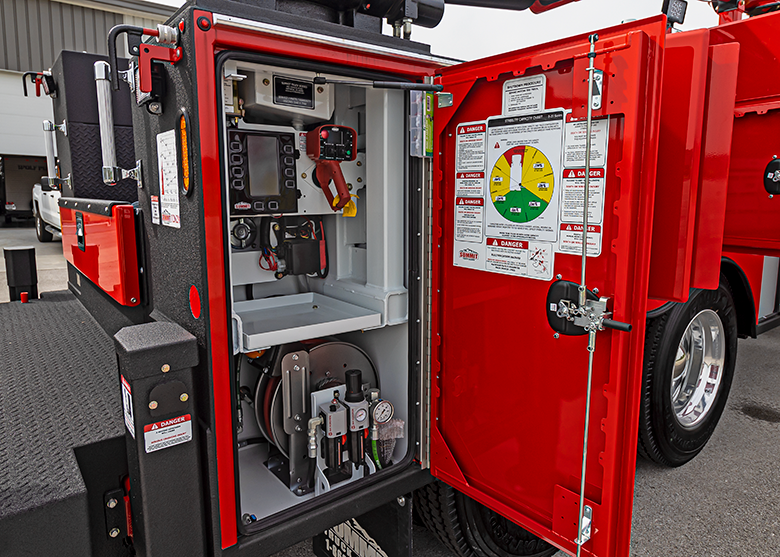

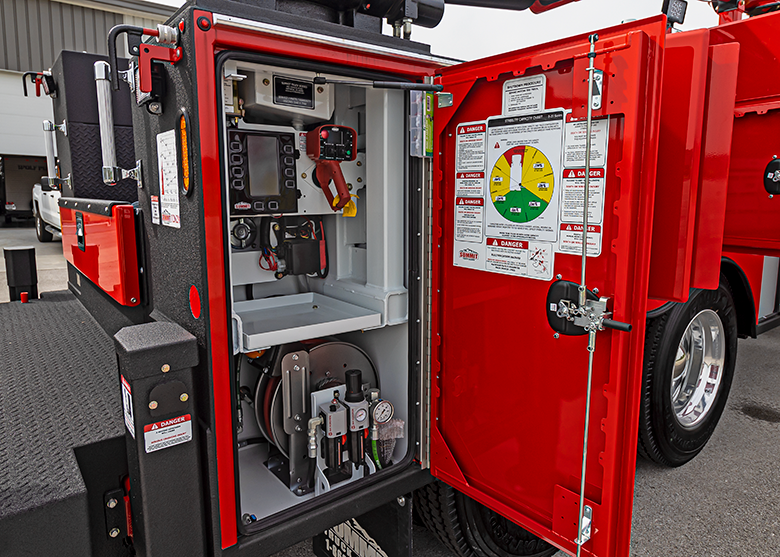

ASE Crane System

We’ve combined crane, body, and chassis operations with functional safety using a network of switches and sensors to communicate data. Advanced Safety Electronics reduces the risks of working in hazardous conditions, takes the guesswork out of crane operation with automated protection features, and gives you information to make safe decisions. Based on the robust J1939 Protocol, we can incorporate telematics data into your fleet management solution.

Design your truck

Contact your regional sales rep to get started on your new custom service truck body.